|

Green Building Industry & Trading Ltd Co.

|

Gold Index: 14515

Product (155)

-

EPS mortar coating machinery

(55)

- CNC cutting machine (36)

- powder mortar mixer (5)

- wet mortar mixer (2)

- acrylic sand mixer (1)

- EPS coating machine (9)

- trimming machine (2)

-

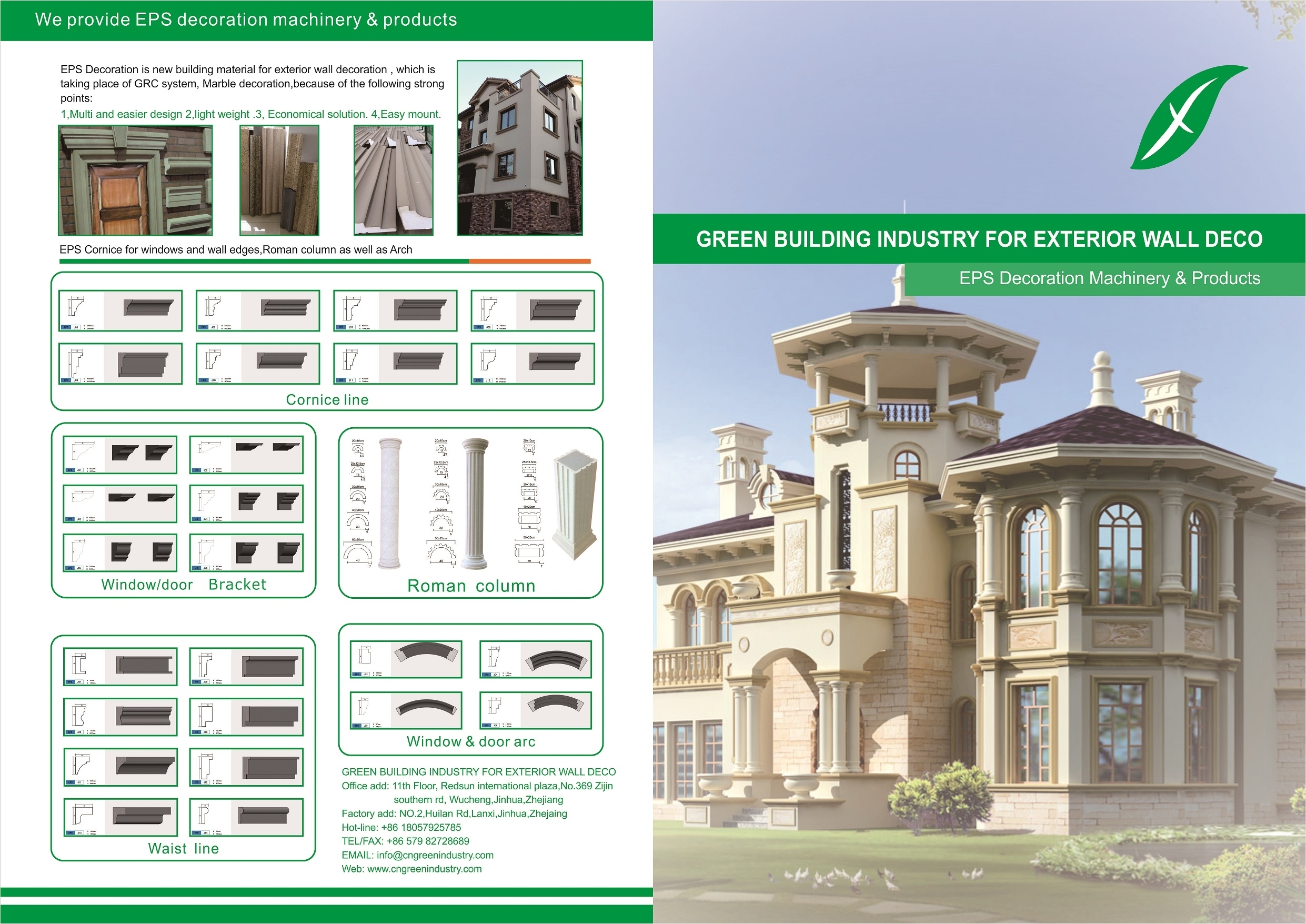

EPS decorative cornice for exterior deco

(66)

- EPS cornice with Acrylic coating (5)

- window pocket (41)

- waist line (14)

- decorative column (3)

- EPS bracket (2)

- EPS insulation decoration board (1)

- GRC cornice for exterior deco (1)

- PS cornice machine for interior deco (6)

- PU cornice injection machine for interior deco (2)

- PS Foam food cantainer production line (5)

- biodegradable food container machinery (5)

- EPS 3D wire mesh panel machine (2)

- EPS sandwich panel machine (1)

- screw air compressor (2)

- water cooling tower (5)

- EPS resin (4)

- Others (1)

Foam coating machine (1)

Customer case (3)

News (11)

high class cornice exported to canada (1)

Certificates (1)

Credit Report

Products Index

News

What is EPS?

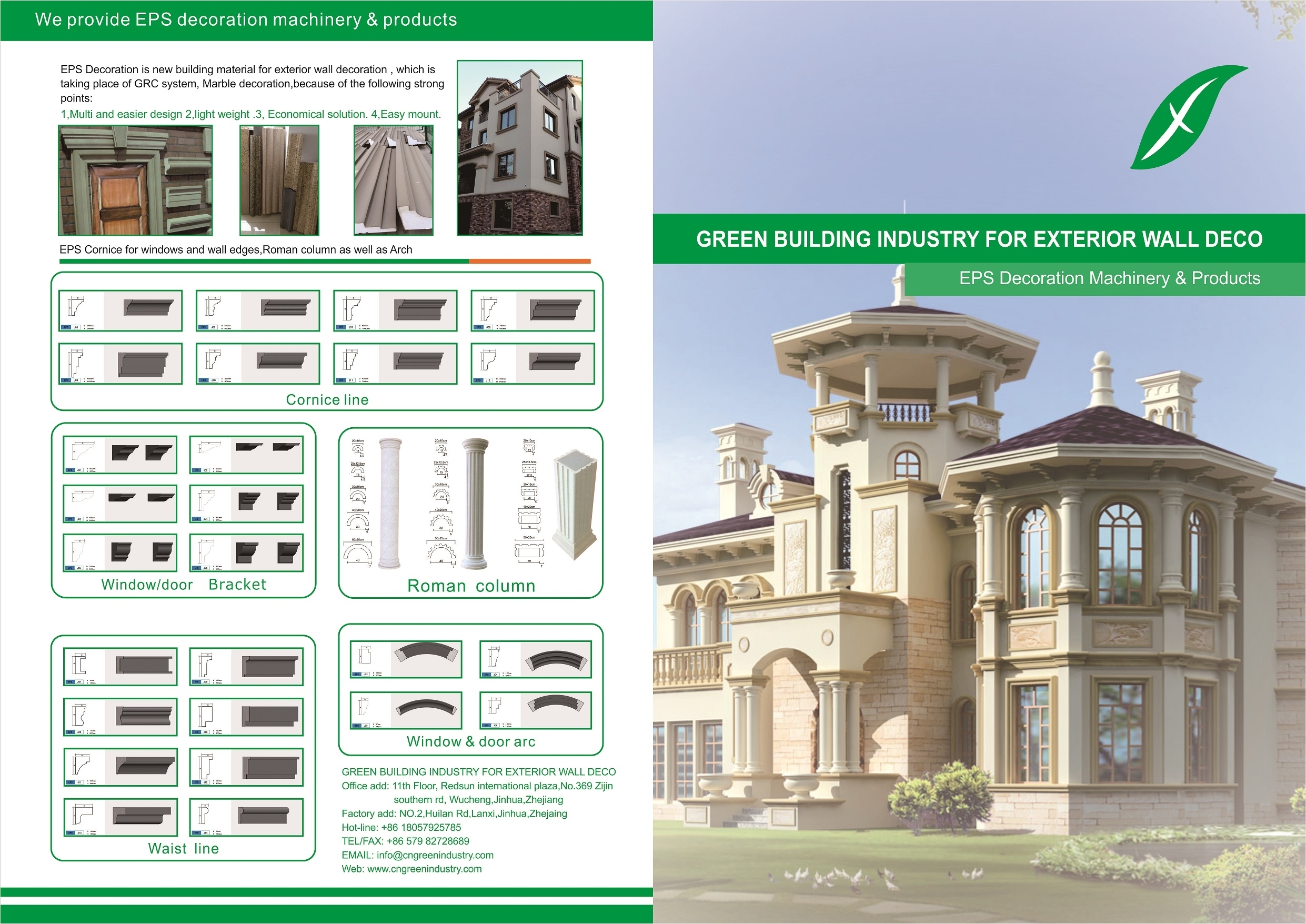

2, EPS board, EPS board insulation system is the clay by special polymerization, composed of alkali resistant glass fiber mesh and decorative materials. Set of insulation, waterproof, fire, decorative functions as one of the new building structure system. The technology will heat preservation material in the exterior wall of the building, do not occupy the indoor space, the insulation effect is obvious, easy to design architectural form.

3, EPS foam is a thermoplastic material, each cubic 200-600 million independent sealed bubble, containing air volume is more than 98%, because the air is very small thermal conductivity, and is closed in the foam and can not flow, so EPS is a very good thermal insulation properties of materials.

Uses: used in the construction of internal and external wall insulation, geothermal heating, cold storage, cold storage room, light body, low temperature box, fresh box

Product specifications (mm): size: 6000 x 6001000 x 2000 x 500

Thickness: 0.5-600

Note: production of various specifications according to user requirements

Technical index

Density (kg/m3): 15-30

Thermal conductivity (W/mh): 0.041

Tensile strength (kg/m2): 2.5-3.5

Dimensional stability using temperature (c): +70

EPS foam is a kind of thermoplastic material, after heating, the volume of each cubic meter of 300--600 containing an independent closed bubble, containing air volume of 98%, so the structure to give it a lot of characteristics. Due to the density of low to 10-30kg/m3, so of EPS is the lightest of packaging materials, under load is high, the material will been bent, when subject to shocks or falling to the ground, he will play a buffer, the role of earthquake; at the same time, due to the thermal performance of air is small and has been closed in the bubbles and not convection, so the EPS is a heat insulation performance is very superior materials.

Use: refrigerator, freezer, refrigerator etc. widely used in civil construction, it is also used to do thermal insulation materials

Pre Page:

The GRC component making and...

Next Page:

EPS deco demo shop in china