|

Green Building Industry & Trading Ltd Co.

|

Stationary electromotor powered single screw air compressor

| Payment Terms: | T/T |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The air compressor air end is composed of one cylindrical worm and two symmetrical plane star wheels,which are engaged and mounted in a casting.

Working Principle of Single Screw Air Compressor

The air compressor air end is composed of one cylindrical worm and two symmetrical plane star wheels,which are engaged and mounted in a casting.The worm groove,casting and the tooth surface form a sealed cavity.The worm rotates the star wheels.When the star wheels moving in the worm groove,the air in the groove is compressed and exhausted.The worm has 6 grooves and is seperated horizontally by two star wheels into two working cavities,each of which realizes seperately suction,compression and exhaustion.Therefore,one single screw air compressor equals one unit six double cylinder piston compressor.

Quality is the only criterion to prove the technology

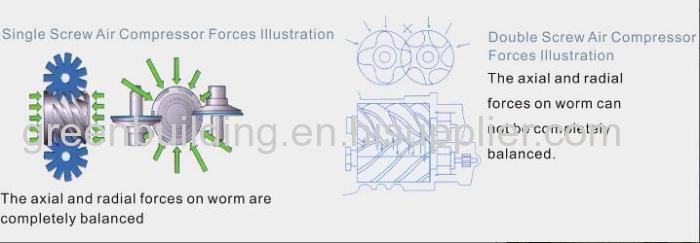

1. Reasonable Structure and Ideal Equilibrum of Forces

As the star wheels are mounted symmetrically on two sides of the worm,the radial air force acting on the worm is balanced,and the axial air load acting on worm groove is also balanced.As the air suction passage is available between two ends of the worm,there is no force on the worm.The tooth of the star wheel only bears a very tiny force,about 1/30 of the double screw air compressor.

2.High Efficiency and Enengy Saving

The depth of worm groove decreases with increases of pressure in compression cavity,it becomes zero when exhaustion ends,and no clearance volume exsists,so the volume efficiency is high.The machine is equipped with complete control system and has automatic air volume ajustment,aotomatic unloading and loading transfer,automatic stop and start functions to meet cunstomers' different requirements.Energy saving is significant and power consumption can reduce 60% in idle running.

3.Long Service Life

Because the axial and radial air forces on worm are completely balanced,the bearing only bears slight gravitational and frictional forces.

4.Low Noises and No Vibration

Due to the air end have a reasonable design with high speed,light load and advanced design of engagement line,no exhaustion pulse is found under 12 compression cycles/rotation of worm and exhausts 35,280 times per minute.As silencing insulating device is uesd,noise is vert low and relatively quiet working environment can be maintained.So a coin can stand on machine without failling down when the machine is full load running.

5.High Reliability

The priduct quality is ensured with advanced design,good process,and high precision special equipment

6.Perfect Controlling and Safe Running

PLC control,man-machine interface,united control of multiple machines,remote and network monitoring are optional.

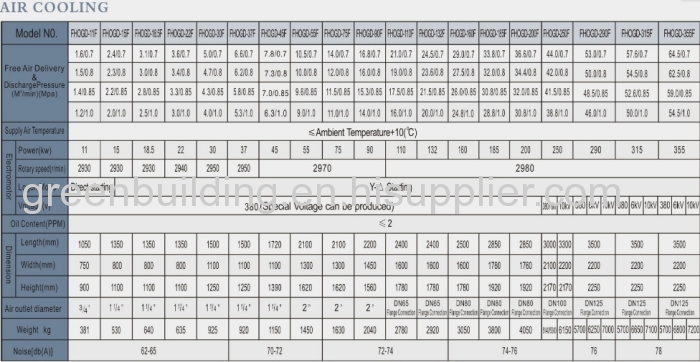

Technical parameters