|

Green Building Industry & Trading Ltd Co.

|

Permanent magnet air compressor

| Payment Terms: | T/T |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Permanent-magnet air compressor,new energy-saving highlight in the air compressor industry.It has advantages of energy-saving and high-efficiency.

Permanent-magnet motor --High efficiency

Rare-earth permanent magnet motor have the following strong points , compare with normal motor.

Highly Efficiency and Energy-Saving

The permanent-magnet motor cancels the loss of excitation system and improves the efficiency,thus having a high power factor,a large moment to intertia ratio,and reduced stator current and resistance loss.In addition,in such circumstance,the rotor parameters can be better measured and controlled.The permanent-magnet motor used in the current air compressor industry can completely meet levell energy efficiency standard.

Slow Temperature Rise

The design of slow temperature rise can greatly extend the service life.The motor,adopting axial flow fan for forced-air cooling,can entirely adapt to the working conditions of frequency conversion.

Power Starting and Operating Tourque

The starting torque is two times higher than the rated torque.The machine can output 100% torque within the operating the rotating speed scope 0 to 100% in order to ensure the stable operation of the air compressor.

Quick Response

The rapid response of the mtor can extensively regulate the gas production rate at an instant to realize constant air pressure.

Accurate Rotating Speed Control

Highly accruate sensors mounted on the machine give real-time feedback on the position of the motor rotor to the controlled of the control of the air compressor,so as to achieve the most accurate regulation of the motor's rotating speed.

Energy -Saving

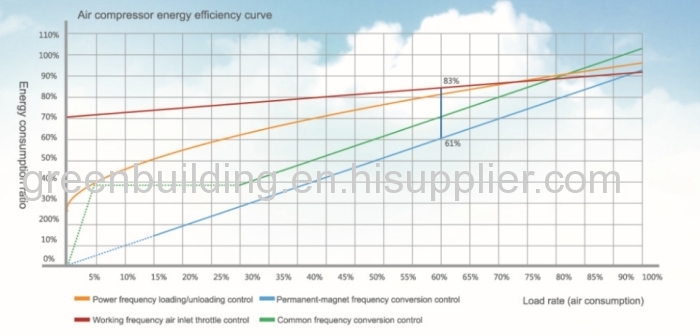

One of the main peoblems with air compressor is their power consumption.Common air compressors generally achieve their optimum working state with an air consumption of 95%,and the energy efficiency decrease sharply with the reduction of air consumption.

Many users have now adopted frequrncy conversion technology to solve the previously mentioned issue.Under the effect of frequency conversion,when the air consumption reaches a certain mean value,the motor of the air compressor will be kept at the corresponding rotating speed.Such a method saves important amounts of energy when compared to common air compressors.Nevertheless,compared to our asynchronous motor,the energy efficiency curve shows that asynchronous motor can also greatly draw down the energy efficiency with decreased rotating speed,leading the air compressor to achieve the most ideal working state.

The permagnet servo air compressor is inclusive of all the advantages of the frequency-converting air compressors,synchronous motors and permanent-magnet rare-earth motors,thus realizing great improvement in terms of energy efficiency.Tests and user experiemce show that 99% of the users can achieve 23% of energy saving,while 90% of the users can save over 36%.The concrete energy efficiency comparison cart is illustrated below.

250KW COMPRESSOR

258012 KW SAVING FOR A YEAR