|

Green Building Industry & Trading Ltd Co.

|

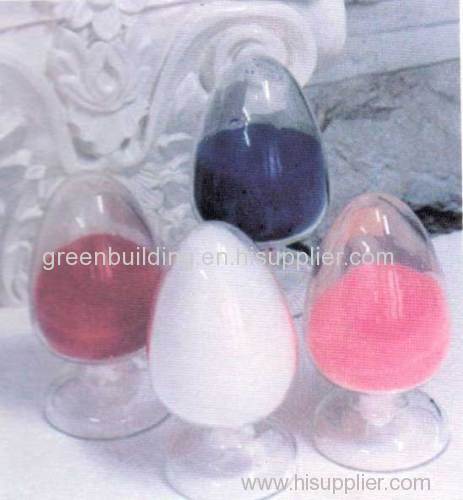

High quality type of PKF

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fast cycling grade is a widely used materials. It can be used in packaging, decorating, moulding and other areas.It is popular in international market

Product Specification

Specification | Bead Size(mm) | One-time Expansion | Application |

PKF-301XS | 1.00-1.60 | 50-70 | Block and low-density product |

PKF-302XS | 0.85-1.25 | 45-65 | General products with thickness more than 12mm and large packaging |

PKF-303XS | 0.70-1.00 | 40-60 | Medium-density packaging |

PKF-401XS | 0.50-0.80 | 40-55 | Packaging with thickness over 8mm |

PKF-501XS | 0.40-0.60 | 30-50 | Packaging with thickness over 6mm |

PKF-601XS | 0.30-0.50 | 20-40 | Special product including full mould casting |

Fast cycling grade EPS confers excellent processing and product properties

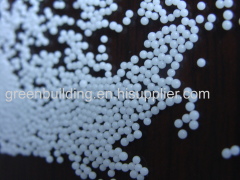

●Consistent raw beads and good fluidity of foamed bead.

●No harmful odors in pre-expansion and moulding.

●Short maturing time.

●Characteristically rapid cooling in automatic molding machines and better performance with vacuum system.

●Uniform cell size, beautiful and flat surface appearance.

●Good integration inside, high resistance.

●Use in contact with food.

●Recommended 40-60 expansion ratio.

Physical Properties

Property | Unit | Density(kg/m3) | |||

15 | 20 | 25 | 30 | ||

Compressive Strength at 10% Deformation | KPa | 65-110 | 100-160 | 140-210 | 180-225 |

Bending Strength | KPa | 160-210 | 240-300 | 325-400 | 410-490 |

Flexural Strength | KPa | 150-230 | 225-325 | 260-415 | 375-510 |

Coefficient of Linear Expansion | 1/K | 6*10-5 | |||

Thermal Conductivity(max) | W/(m*k) | 0.35 | |||

Specific Heat | KJ/(kg*k) | 1.21 | |||

Recommended Proceeeing Condition

●Material Selection

Select proper bead diamaters according to the required shape and density of the final product. Large articles in medium and low density (less than 16g/I) require 302XS or 301XS. Continuous pre-expanders require 302XS or 303XS while batch pre-expanders require 303XS/ 401XS / 501XS.

●Pre-expansion

Steam Pressure: 0.15MPa-0.30MPa

Pre-expansion Temperuture: 96-108℃

Condition Time: 4-24 Hours

●Moulding

Steam Pressure of Stationary Mould: 0.7-1.2kgf/cm2

Steam Pressure of Moving Mould: 0.75-1.2kgf/cm2

Health and Safety

●Fast cycling grade totally meets food cintact safe requirements as is less than 0.2% wt/wt. The total comtent of aromatic hydrocorbon impurities are far lower than the one in similar competitive products.

●During storage, transportion and processing, low levels of pentance blowing agent will be present, which will have an explosive range in air between 1.1-6.0%. The raw material and products must therefor be well ventilated and kept far away from sourse of ignition including static electricity.

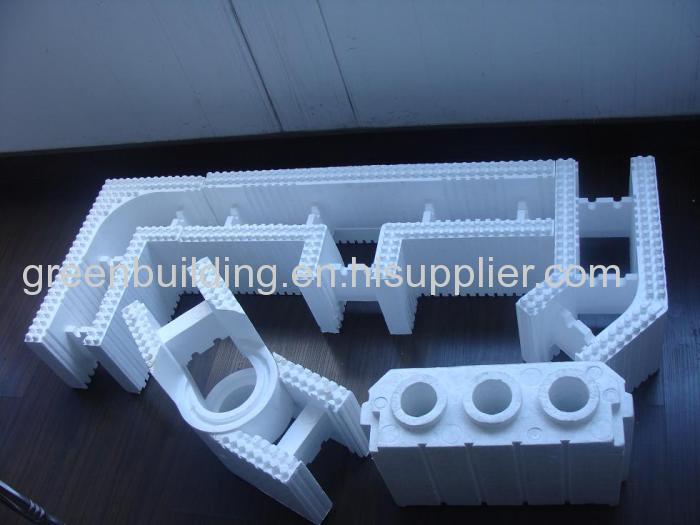

Application