|

Green Building Industry & Trading Ltd Co.

|

High expansion efficiency EPS

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PKF-XJ light material is the regular EPS grade widely used in expandable polystyrene and is suitable for automatic vacuum molding machines, traditiona

Applicability

PKF-XJ is the raw material of high expansion ratio for the production of low-density beads by one-time expansion and is even suitable for marking lighter plastic foam by several expansion steps. It is therefore most suited to applications requiring densities of less than 18g/l by one time expansion and 10g/l by several expansions. Applications include machinery and electronic product packaging, fishing flotation buoys, crafts, well as light board.

Product Specification

Specification | Bead size(mm) | One-time Expansion | Allication |

PKF-301XJ | 1.00-1.60 | 70-90 | Large packaging, thermal insulation and heat preservation, block, flotation buoy |

PKF-302XJ | 0.85-1.25 | 65-85 | General packaging, thermal insulation and heat preservation, light block |

PKF-303XJ | 0.70-1.00 | 60-75 | Thin article packaging, block |

PKF-401XJ | 0.50-0.80 | 55-70 | Tiny article packaging, block |

PKF-501XJ | 0.40-0.60 | 50-65 | Fine packaging, block |

PKF-601XJ | 0.30-0.50 | 35-50 | Fine packaging |

Outstanding Properties of PKF-XJ

●Fast expanding and high expansion ratio in unit time. Energy -save and efficient.

●Low density after expansion (10.5-15g/l), suitable for low-density products.

●Even lower density after several expansions,satisfying the requirement by low-density block products.

Recommended Processing Conditions

●The processing of EPS consists of pre-expansion, maturing stage, block molding and shape molding.

●If several expansions are needed, the first expansion should be specially noticed controlling the interval between expansions within 3-6 hours (short in summer while long in winter ) in order to avoid the expanded beads being over-shrinked. The time in marturing stage directly influence the highest ratio and hardness of block.

●The low-density block should be removed the inner water in heating room in order to improve the output ratio of block and to make the cut block surface smooth.

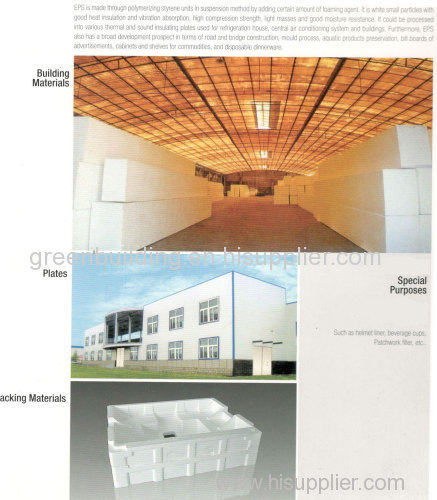

Application